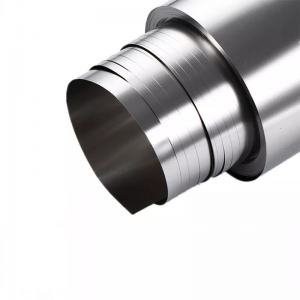

Titanium tube

| Material | CP titanium, Titanium alloy |

| Grade | Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 etc |

| Size | OD: 3~1500mm, WT: 0.2~25mm, Length: ≤19000mm |

| Standard | ASTM B338, ASTM B337, ASTM B861, ASTM B862 etc |

| Status | Annealed (M) |

| Technology | Rolling, Welding, Machining |

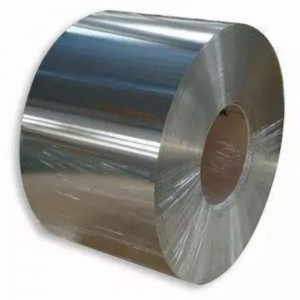

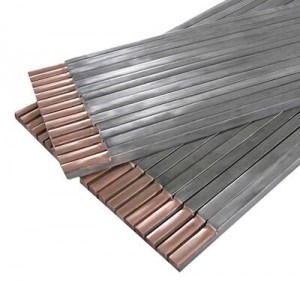

| Grade | Condition | Specification | ||

| Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11,Gr12, Gr16, Gr23 | Hot Rolled(R)Cold Rolled(Y)Annealed(M)Solution treatment(ST) | Thickness (mm) | Width (mm) | Length (mm) |

| 0.1-2.0 | 10-500 | ≥500 | ||

| Grade | Chemical composition, weight percent (%) | ||||||||||||

| C≤ | O≤ | N≤ | H≤ | Fe≤ | Al | V | Pb | Ru | Ni | Mo | OtherMax each | OtherMax total | |

| Gr.1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr.2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr.4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr.5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | - | - | - | 0.1 | 0.4 | |

| Gr.7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12-0.25 | - | 0.12-0.25 | - | 0.1 | 0.4 |

| Gr.9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5- 3.5 | 2.0- 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr.11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12-0.25 | - | - | - | 0.1 | 0.4 |

| Gr.12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6- 0.9 | 0.2-0.4 | 0.1 | 0.4 |

| Gr.16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04- 0.08 | - | - | - | 0.1 | 0.4 |

| Gr.23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5- 6.5 | 3.5- 4.5 | - | - | - | 0.1 | 0.1 | |

| Grade | Mechanical Properties | ||||||

| Tensile Strength Min | Yield Strength (0.2% offset) | Elongation in

50mm Min(%) |

|||||

| Ksi | MPa | Min | Max | ||||

| Ksi | MPa | Ksi | MPa | ||||

| Gr.1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr.2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr.4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr.5 | 130 | 895 | 120 | 828 | - | - | 10 |

| Gr.7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr.9 | 90 | 620 | 70 | 483 | - | - | 15 |

| Gr.11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr.12 | 70 | 483 | 50 | 345 | - | - | 18 |

| Gr.16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr.23 | 120 | 828 | 110 | 759 | - | - | 10 |

Chemical composition test

Physical properties test

Appearance defects inspection

Flattening test

Flaring test

Hydrostatic test

Air tightness test

Ultrasonic flaw detection

Eddy current testing

In order to avoid the titanium disc has any collision in transit or damage, usually wrapped with pearl cotton (expandable polyethylene), then packed into wooden case.